Environmental

For many years now, we are focusing on issues where we can make significant contributions to cutting our environmental footprint such as Responsible consumption and production (SDG 12) and Climate action (SDG 13).

Resource Management and Environmental Impact Management

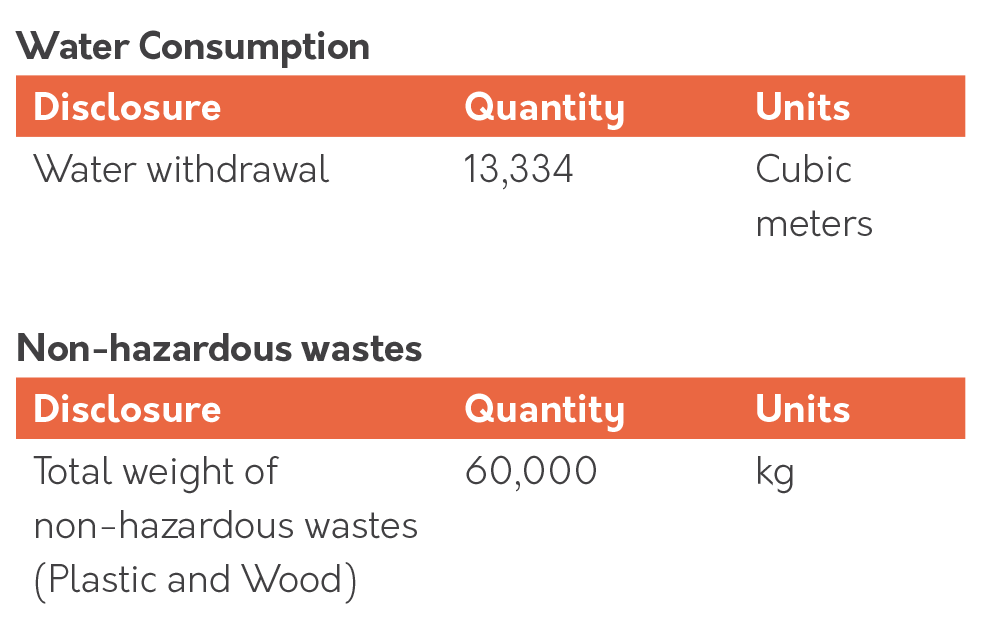

Our data was obtained from the Central Exchange Station (CES), which is meant to be representative of the data collection process for this preliminary report and will guide the needed data calculations for the next report.

Our impact

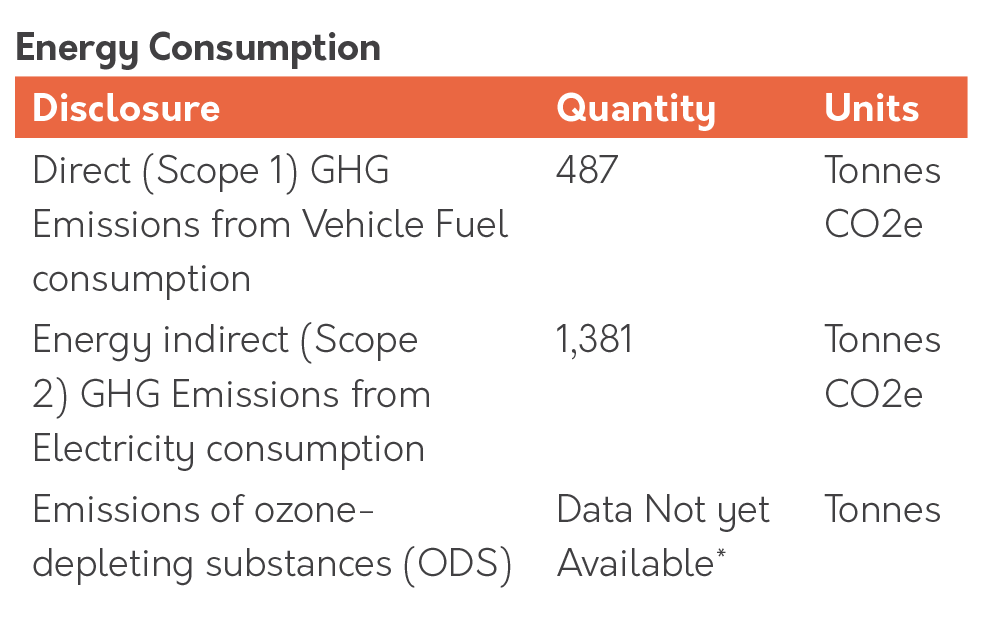

Energy and waste are among the top sustainability issues for the logistics and transport sector, and similarly what came up as aspects of our operations that are material for our stakeholders.

The energy consumption we presented here includes our direct impact on GHG emissions from vehicle fuel consumption as well as indirect GHG emissions from electricity consumption. For vehicle fuel consumption, it tracks the consumption of shuttle vans which travel to and from CES but excludes delivery trucks and is not representative of the whole fleet. For electricity consumption, on the other hand, it represents our total electricity consumed in 2018.

Our management approach

As part of our management’s decision to do the right thing, we’ve made decisive contributions to changing the world we live in for the better. We rolled out several initiatives voluntarily prior to any pressure or requirement from regulators or other stakeholders. For example, in 2012, we introduced biodegradable pouches long before the fight against plastic waste became mainstream in the country. Certified 100% oxo-biodegradable and safe for human use, this packaging breaks down in 1 to 1.5 years when exposed to degradation promoters such as heat, light, or microorganisms such as those in landfills. It does not emit methane when degrading vs. other plastics, including those with cornstarch-based additives. In 2018, we issued 140,000 of these pouches daily.

In 2017, we launched our digital transformation and began to automate key processes and technologies and integrate those changes into our culture. We have installed “Put-to-Light” (PTL) sorting system which enhanced our efficiencies in Central Exchange Station—our 24/7 consolidating facility in Metro Manila which sorts approximately 175,000 packages per day from all over the Philippines. This light-directed sortation system is a quick, convenient, and highly intuitive approach to automating the tedious work of manually sorting parcels and packages, at the same time, increasing accuracy by 99% and speed of sorting by 30%.

Another project is our installation of solar panels in our Davao warehouse for better energy management. We’ve engaged Green Energy to provide us with a solar-generated power system that has approximately 100kW power capacity. This represents 35% of the 300 kW maximum required power needed of the warehouse. We look forward to sharing the results of this initiative in our next report.

Risks and Opportunities

We are a data-rich logistics company with over 70 years of operating history. But what this sustainability journey has taught us is that there is always room for improvement particularly on data collection, infrastructure, and report quality. We look forward to lead the way for completing our environmental data in the next report, in this case, energy consumption (stationary fuel, vehicle fuel, and electricity), water and effluents, air emission, and solid waste (non-hazardous waste) to sufficiently reflect the full impact of our operations and allow our stakeholders to assess our performance and track our progress.